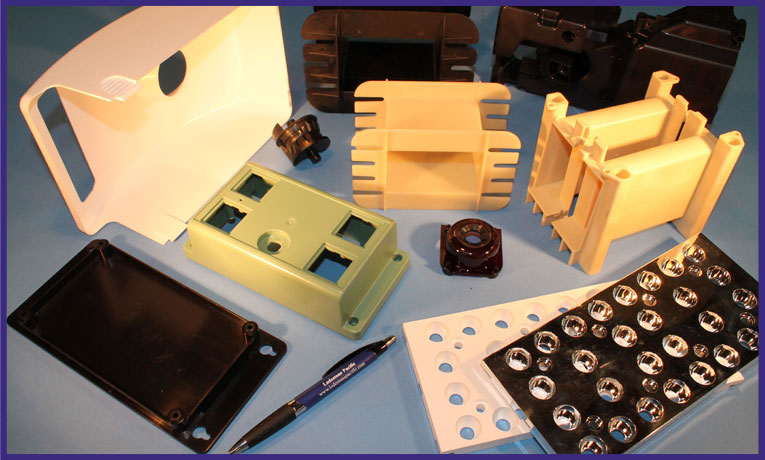

Custom Molding & Tooling

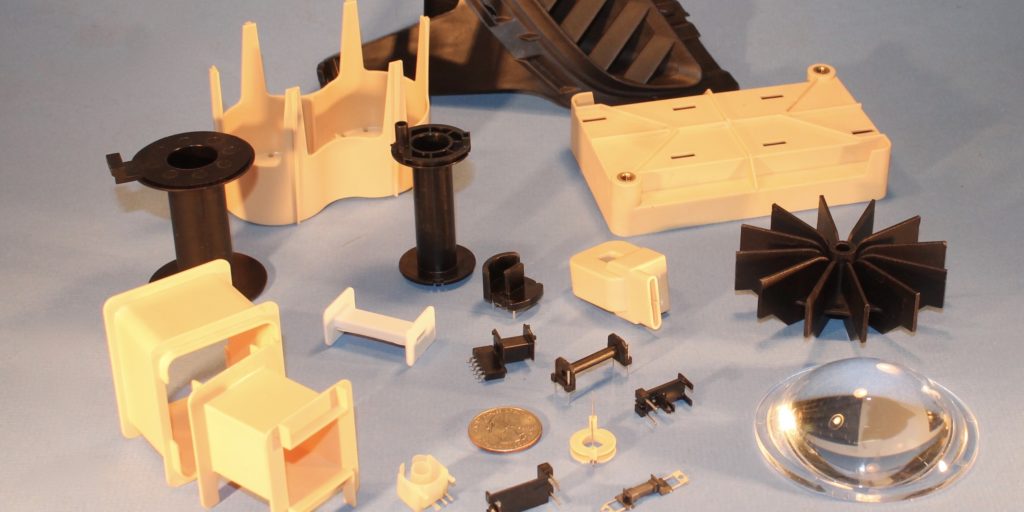

Custom Plastic Molding

Lodestone Pacific has extensive tooling, molding, and metal fabrication capabilities in Shenzhen, China. With over 20 years of experience manufacturing in Southern China, Lodestone Pacific can provide new custom tools in 3 weeks, first articles a week later, and production 2 weeks after first article approval. Let us quote your next opportunity.

Molding Capabilities

Thermoset Plastics:

- DAP

- Phenolic

- Epoxy

Thermoplastics:

- Glass Filled Nylon (GFN)

- Poly Butylene (PBT)

- Polyethylene (PET)

- Polyphenylene (PPS)

- Liquid Crystal Polymer (LCP)

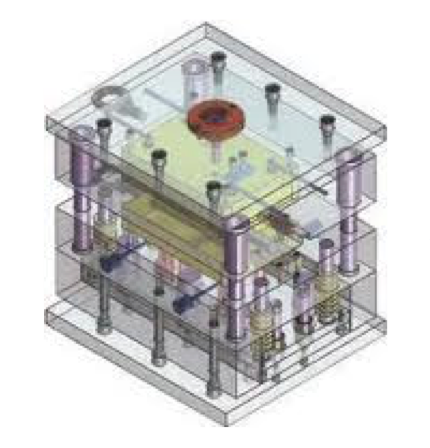

CAD/CAM Capabilities

Lodestone Pacific can produce quotes or tooling from your CAD drawings or create CAD 3D STEP files from your 2D drawings.

CAD/CAM Experience, DWG, DXF, DRW, PRT, XPR, DFT, SLDPRT, and STEP File Formats

Tool Design and Tool Making

Lodestone Pacific has the experience and resources in China to develop and produce high-quality cost-effective tools in 3 weeks, with 1st articles ready for your approval in 4 weeks.

Plastic Molding

Lodestone Pacific can do transfer molding and injection molding of a variety of materials with both molded-in terminals or after molding inserted terminals.

Post Production Capabilities

Lodestone Pacific can insert terminals, sonic weld, silk screen, pad print and assemble your moldings.

ISO-9001 Quality System

Lodestone Pacific maintains a quality system that ensures ISO-9001 quality guidelines are followed. Inspection documents and internal audit records are available for customer review.